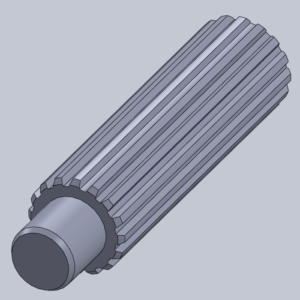

Many of the various parts sold on the Orion Ranch Observatory website are 3D printed to order based on custom ORO designs. The parts are manufactured using a process known as fused deposition modeling (FDM) where a plastic filament is melted and extruded onto a build surface, constructing the part line by line and layer by layer. Unless otherwise noted, these parts are manufactured from a biodegradable plastic known as polylactic acid (PLA), which has good mechanical stiffness, but is subsequently somewhat brittle in comparison to other more flexible plastics. Its overall properties make it the most popular choice for FDM printing.

PLA is a relatively low temperature plastic and thus some care should be taken to avoid extreme environmental conditions. I’ve designed and tested these parts under a wide variety of conditions including using black PLA parts in full sun on 100+ degree days, so under normal use they can be expected to perform fine. However, extreme conditions such as storing a part in a hot car under stress (e.g. a tripod spreader cinched down tight) will likely result in the part “relaxing” to a new shape.

3D printed parts generally exhibit a “grain” as a side effect of the printing process, and some level of warping and cosmetic imperfections is common. These do not affect the usefulness of the part for its intended purpose.