As mentioned in the last post, in late October the roof bound up on the rail system when opening. I just happened to be there when I was opening to hear a long wood on wood squeal as something dragged for the last couple of feet. Luckily I was only going halfway open to begin with. I imaged overnight, and in the morning, on trying to close the roof, it moved about a foot before stalling and losing the new web interface I’d developed. Turns out it blew the fuses on the motorbase rather than tripping the breaker. I was able to climb up and swap them and get things closed, but figured I’d better not try to open it again until I’d done a more thorough inspection.

Two years ago, I’d discovered some bad rot on one of the posts and diagonal braces, so had braced all of that and reinforced it, but a hammer tap test around the rest of the rail system didn’t show any soft spots.

Initially, I’d planned to redo the entire rail system in steel that winter and had started working on an I-beam (really a wide H-beam) design to replace it. Unfortunately, with the new job I really haven’t had time to take off to do that (or even finish the design). The re-braced and reinforced post has held up pretty well, with no evident growth in the rot, so I was actually debating just replacing that one post and seeing how much longer I could go.

Sadly, after doing a more thorough inspection of the rail system, it was in pretty bad shape and not something that a bit of maintenance would easily address. Certainly not something worth throwing money away on more wood. The diagonal braces on the opposite side middle post were shot.

And the bottom of the cross member was rotting away too.

The top of the east rail looked ok, but the west rail where all the noise came from was in pretty bad shape.

There were spots where the top cap had rotted through.

And the underside of my laminated triple 2×12 beam looked like it was separating.

At any rate, it doesn’t look like I’m going to be reopening again for a while! I’m going to try to finish my redesign and order the H-beams to redo all of this in steel, while I still have the strength to be able to handle a project like this! If I can get the design done and get the materials ordered in time, I might be able to take off Thanksgiving week to attempt the rebuild. Of course nothing ever goes as fast as I hope, and I don’t have the stamina I used to to boot, so finishing it all in one week may be a stretch. I figured I’d start this thread to track the progress of the rebuild and share the results.

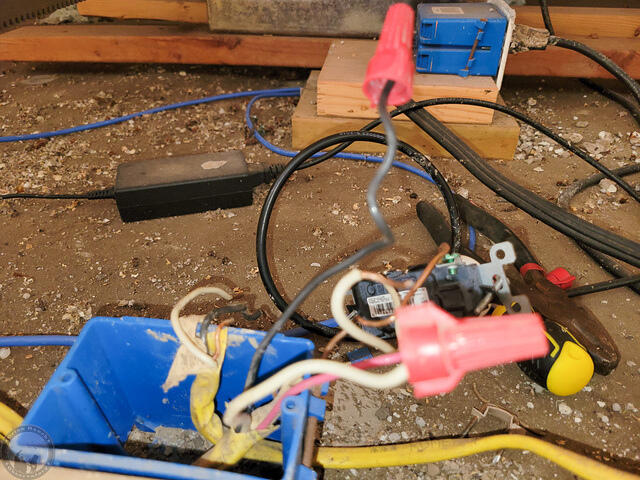

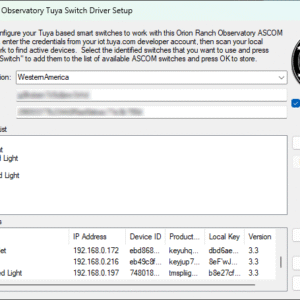

The sad thing is that I was almost to the point of finally fully automating my observatory! I just finished my ASCOM driver to control Tuya SmartLife smart switches, and with my new ESP32 based web controller for my roll-off, was planning to write an ASCOM driver to support that as well. So of course my luck says it’s time to shut me down with some other problem! As I mentioned in the OnStep rebuild video, if I ever win the lottery, it’s time to head for the hills or find a church and start praying, ‘cuz the world is a comin’ to an end!

November 1st, 2025

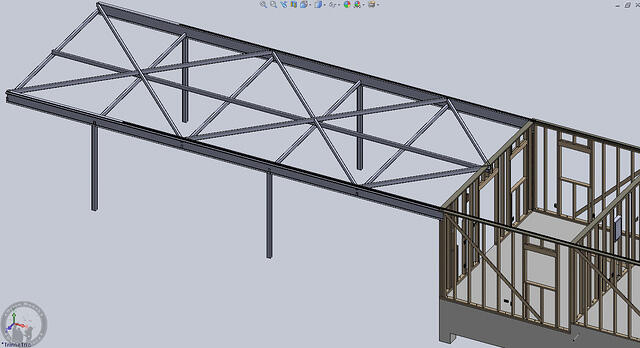

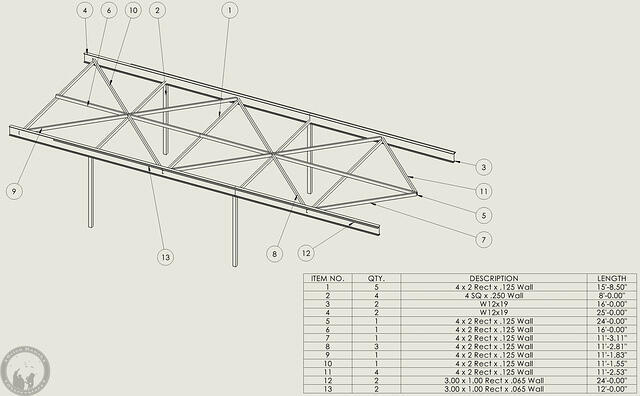

Here’s my initial plan for replacing the wood rails with steel. This will depend on whether I can get 40′ H-beams delivered and onsite vs. having to use 20′ beams. If I have to go with 20’s, then it will be 4′ shorter. I don’t really need the extra overhang, but it would be nice to have the option of moving the roof completely off if I ever needed to service the wood in the observatory itself. The bracing may be overkill, but this should minimize any chance of twisting, etc. on the beams. I haven’t decided on bracing for the posts.

December 19th, 2025

Ok, so the steel is on order and I’m planning to start demolishing the existing rail system tomorrow.

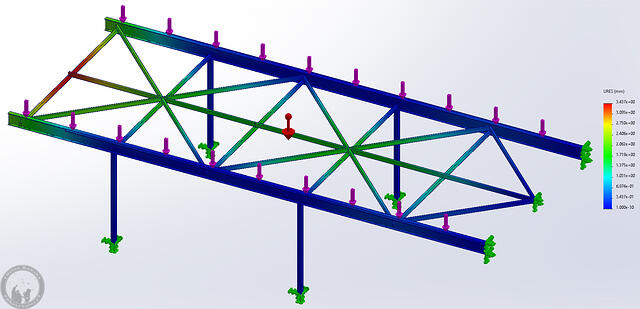

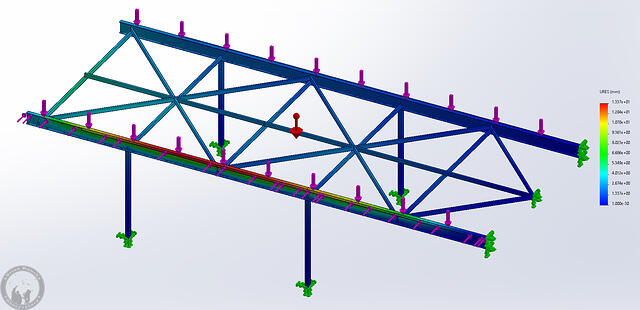

I’ve run some static load simulations to confirm how strong this will be under load. The most sag under gravity is just the bracing cross members that will sag a mm or two under their own weight. With the roof rolled completely off the observatory (observatory wall/rail repair mode) so that it’s out on the 9′ overhang I’m going to have, the H-beam will move about 1.5 mm. Normally the roof will remain over the warm room and never go out on the overhang, so it’s really just because I was going to have to pay for the metal regardless, so why not use it?!!

I did have to lower the diagonal cross braces to be on the centerline of the beam rather than up at the top, since I’d forgotten that the end cap of the roof hangs down past the top of the rail. So I don’t have quite the amount of twist prevention that I would have had, but I don’t think it will be a problem. I applied 10,000 lbs of force to the edge of the top flange and it only moved 33 mm (about 1.25″). Applying a 100 MPH horizontal wind load on the entire roof gives about 3500 lbs of force, assuming the roof was really a flat surface. I suspect the angle of the roof would convert much of that force to downward force instead of horizontal, but still, that’s showing a worst case of ~13 mm (half an inch). Hopefully I’ll never have the roof open in 100 MPH winds, but if I were to do so, I don’t think the rails would be going anywhere!

Here’s the final plan.

December 23rd, 2025

Well, now that I have a trailer load of steel, looks like I’m committed (or should be committed)! So tomorrow I start demolition of the old rail system. Had hoped to have that done or at least underway by now, but spent the time cleaning up the area and trimming some trees to have room to work and install some cameras for timelapse capture.

December 24th, 2025

Demolition Picture Time!

Started by removing the red strip light and lighting conduits from the center longitudinal brace. That required opening the roof one last time to disconnect the wiring from the junction box above the warm room.

Look at all that wasp nest debris! Ugh! Going to have to get up there with a shop vac after I finish all of this.

Here’s where I pulled the conduit out of the caulk.

Next came pulling down the pole with all of the TV and cell phone booster antennas and removing all of the associated cables. With the hail storms, etc. they are all rather worse for wear. Not sure I’ll be putting any of this back up now that we have satellite internet, but it did make for a good lightning rod and north direction finder for my all-sky camera alignment!

Speaking of lightning, the center pin of the TV antenna cable was burnt off at the grounding terminal. I would expect lightning to primarily be carried on the shield, so it’s more likely it was the DC power supply that ran the amplifier in the antenna when all of that probably got shorted out with the busted housing and rain.

Then came removing the last detritus of the different cameras I’d had mounted to the rails at different times.

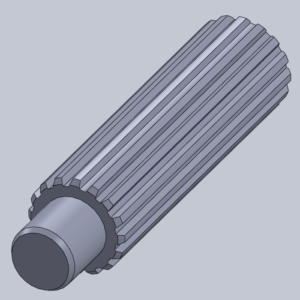

From there, I had to remove all of the angle iron for the V-grooves. I didn’t buy enough extra angle to completely replace all of this, but I’m wondering if that was a good idea. There was a considerable amount of loose rust underneath some of it, and there are the holes and notches for screwing it down that I just plan to weld over and grind flat. I don’t think the integrity is really compromised, but I’m debating if I should run a bead down the entire length on both sides to keep water out. That’s a LOT of welding and welding wire! We’ll see. Worst case, I may paint, caulk, and paint. I have the same situation with the two 1×3’s that will be creating the necessary overhang to match the existing roof capture system.

Here’s the top of the east and west rails, respectively. Both pretty wavy, although the focus isn’t good across the depth.

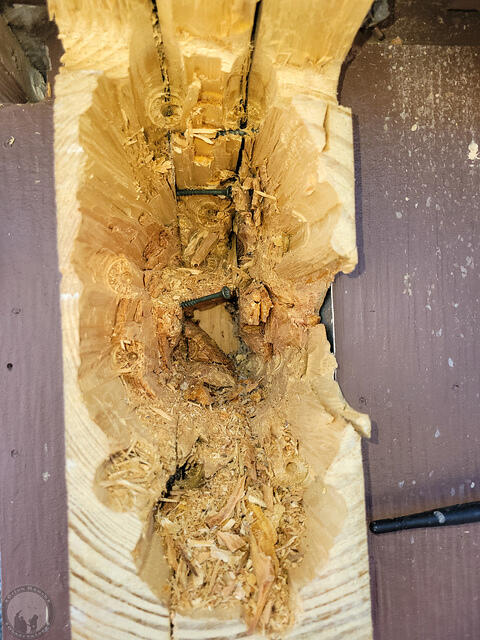

This was really the amazing part, where the wood basically split on either side of the angle, so all the water was going right down into the rail cap.

These pictures are all from the west rail, which had the worst of it, but as you’ll see later, it was really only the cap piece. I didn’t remember until I was taking it all down that I’d actually come back and spaced the cap off with wedges to correct for the sag that occurred as it dried. Thus, while caulked closed, there was a gap between much of the cap and the rail beam itself. This is the worst rot area shown previously. From the surface, it actually almost looks like the wood was burned, largely because the surface was so blackened, but the pieces look the same as what you’d get if you wet down a mostly burnt log to put it out. Does make me wonder again about a possible lightning strike, although for the most part it’s just rot. No insects though.

Here’s an example of the rust under the angle in one of the less rotten areas.

The screws holding down the angle were in various states from fine to sheared off at installation to eroded down to sharp little points. I suspect some of the latter is from the dissimilar metals in the pressure treated wood interacting with the steel in the screws where the paint was abraded at installation.

Finally, I had to make a temporary stand to hold the weather station and get it moved without bouncing it around too much to “make it rain”. I should probably be sending it off to be refurbished while I have it down, but I really hate being without it.

And now the rail system is clear of everything but wood and screws!

Next up — Tearing it down!

December 25th, 2025

Here’s wishing everyone a Merry Christmas!

December 26th, 2025

First Cuts! Using my chain saw to take this down quickly. I had to sharpen the chain by the time I got to the last rail as it wasn’t cutting anything. I probably hit some screws along the way. Either that, or the pressure treatment was especially hard on it. Cut through all of the diagonals at the post and removed the end rail cross brace in one piece.

Then came the center longitudinal sections and mid-span cross brace.

And then the first 16′ rail section. I basically cut the top off the post on the outer part since the post is actually integrated into the middle of the beam, and then cut away from the rest of the rail system through the beam. Really was painful cutting through the perfectly good beams!

Taking down the second beam, which was the tallest and had the most rot, I ended up dropping it. Trying to pick it back up by hand to get it into the bucket, the top rail crumbled, revealing the perfect beam underneath, as well as all of the wedge spacers I’d used to get the top perfect. It was also amazing just how light the triple laminated beam was! Putting it up, I remember that I could barely lift one soggy 2×12 into place at a time! Now the entire beam probably weighs about what one 2×12 did!

Next, I removed the nails from the post holders at the base and dropped the first two posts. Again, pretty light. They’d started out with lots of cracks that I’d caulked originally, and there was some evidence of weak areas, so I would have wanted to replace all the posts and the top cap, along with all of the diagonal bracing, etc. if I’d tried to restore it vs. replace it. Just as well! And again, they were incredibly light compared to new wood.

Half way there!

The second 16′ section pretty much proceeded like the first, although I had to leave an overhang from each rail to avoid risk of damaging the soffits and gutter, as well as because there’s still an overhanging piece of angle iron from the observatory. Still need to decide if I’m leaving it or cutting it at the seam to the new rail. Right now I’m proceeding as though I’ll be leaving it.

Anyway, first comes the middle cross brace and longitudinal braces, followed by the mid-span brace.

Then the east rail beam.

Followed by the west rail beam.

And the last two posts.

Resulting in my completely denuded observatory. Actually looks like a pretty normal building now!

Of course, in the process I noticed something that I actually believe I saw before and completely forgot about. Either this was one particularly angry piece of hail, or more likely from the angle, an errant rough-housing Texas Longhorn! I certainly don’t recall doing anything myself that would have caused this, although I can’t guarantee that no one else did.

There are also a bunch of dents I need to straighten out on the condenser of the new AC unit I put in place of the old one that failed. I don’t think the longhorns would be knocking on something this high, but that would have required some pretty horizontal hail to be getting past the top of the old outer cover.

Next Episode: Getting a Rail out of a Wall!

December 27th, 2025

I’ll have to check the timelapse later, but this took me the better part of a day to get this rail removed without damaging everything else. First I had to remove the big cell phone booster cable I’d run through on this side. The other one with the small RG cables and ground wire will be even harder to avoid damage. Still, after dulling two spade bits beyond use and a lot of chiseling, I finally got the entire rail out. Need to decide if I’m going to keep that overlapping cap board or not. Probably not.

First I’d started by working to cut the bulk of the beam away from the top cap and building before giving up the night before. The top cap is screwed into the remaining angle iron and there’s no way to remove the screws from the top, so I have to work up to them.

Eventually, I got there the next morning.

Then it was drill, chisel, drill, chisel. Here you can see a couple of the screws holding the laminated beam together (along with the large amount of construction adhesive!). So much for the first drill bit!

Once I got down to the back of the beam at one point, it started going a bit easier, although that outer/right 2×12 was EXTREMELY tough! Hard to make much progress on it with the chisel.

And of course there are screws and nails into this from all sides.

Eventually, I got the entire laminated beam out, but still needed to get the top cap loose from the four screws holding it to the angle iron. You can see all of the nails that hold the insulating sheathing, siding, and trim to the beam. I’ll have to cut those off and re-nail everything into a spacer board I insert after the metal beam is in place.

After lots of careful sawing around where the screws were from underneath, I eventually was able to pry the board loose without messing up the angle iron.

If this weather improves, tomorrow I’ll be out there working on the other side! Hopefully it will go a bit faster, but we’ll see. In the meantime, here’s a video I took while up on the ladder finishing this up.

The other thing that’s been going on during this period was me working on getting my Adobe Lightroom plugin for Gallery 3 working with the latest version of Lightroom so that I could upload pictures from my new Nikon Z8 camera I bought myself for Christmas (on Black Friday!). The site from the guy who wrote the plugin originally is down and no one can contact him, so I had to decompile the Lua script, fix all the bugs that introduced, and update it myself!

In the meantime, with the observatory shut down, I’ve really been missing any opportunity to do some observing. So, a week or so ago, on the coldest, windiest night to date, I finally brought the traveling 8se setup over from the observatory and set up to get our first look at Orion for the year.

December 30th, 2025

Another five hours of effort gets the other rail end out of the observatory. Still have to deal with all of the screws, etc.

This is a cleaned up summary of the first page of my posts on Cloudy Nights in the thread, Orion Ranch Observatory Down for the Count. As always, there are many more images in the gallery, so follow the links icon to jump to the associated page and browse from there.